- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 38 Author: Ren Pan Publish Time: 2017-09-26 Origin: Site

Flammable, volatile products are often tested for their Flash Point or Autoignition point to characterise them.

But what exactly is the difference between these two tests, and what do the results mean?

Definitions

Flash Point – is the lowest temperature that the vapours of a material will ignite when exposed to an ignition source.

Ignition Temperature (Autoignition Point) – is the lowest temperature that the material vaporises into a gas which ignites without any external flame or ignition source.

Overall this makes flash point a more common test, and it is commonly used to assess the fire hazard of liquids.

Flash point is tested by a range of standard methods, which all vary slightly in their method. The most common methods include ASTM D92, D93 and D56 – but there are many others from ASTM and IP standards.

All methods can be broadly split into open cup flash points, and closed cup flash points .

All have a similar method of testing – the liquid is heated to produce vapours, then an ignition source is applied and (either manually or automatically) a flash may be detected. If no flash is detected, the heating continues. When a flash is detected, the temperature is recorded as the flash point.

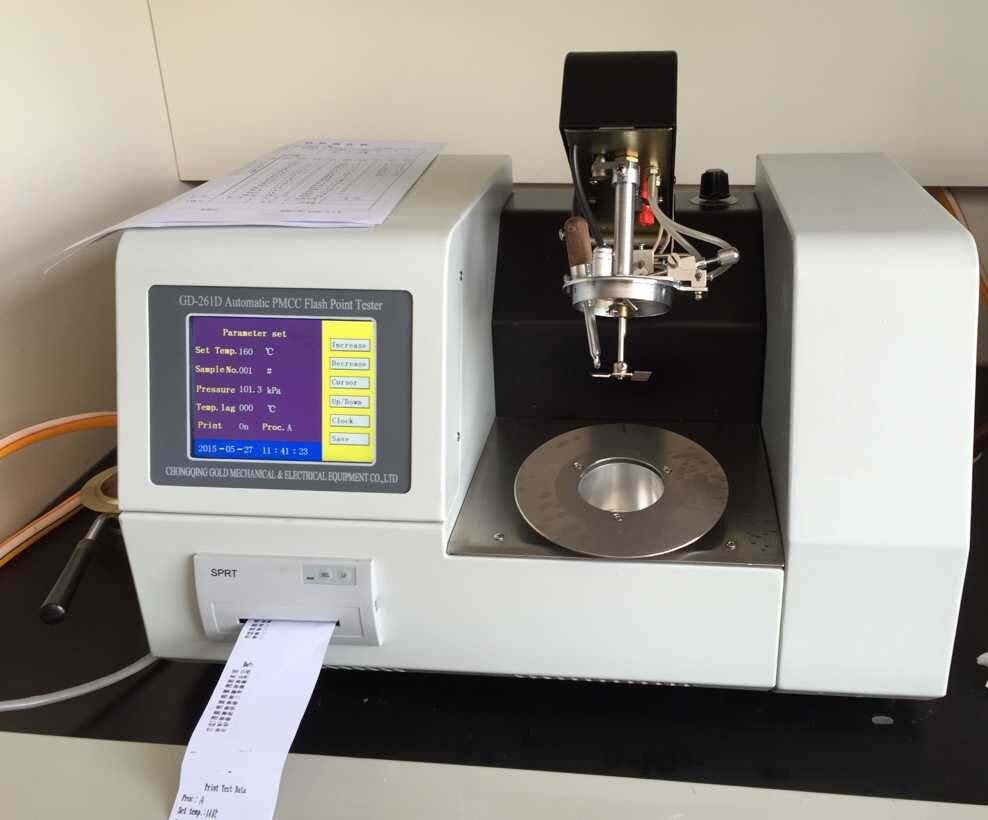

An automatic Pensky Martens Closed Cup flash point tester–

just one of the many flash point test methods available

The main standard method for Ignition Temperature testing is ASTM E659.

The test involves heating a vessel containing the liquid sample in an enclosed oven, then measuring when ignition occurs. Due to the hazardous nature of the test this is all automatic.

Autoignition or Ignition Point apparatus

CQGOLD are pleased to offer equipment for testing Flash Point or Ignition Temperature – our range covers manual and automatic options for all major ASTM and IP test specifications.