- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

GD-ND21B

GOLD

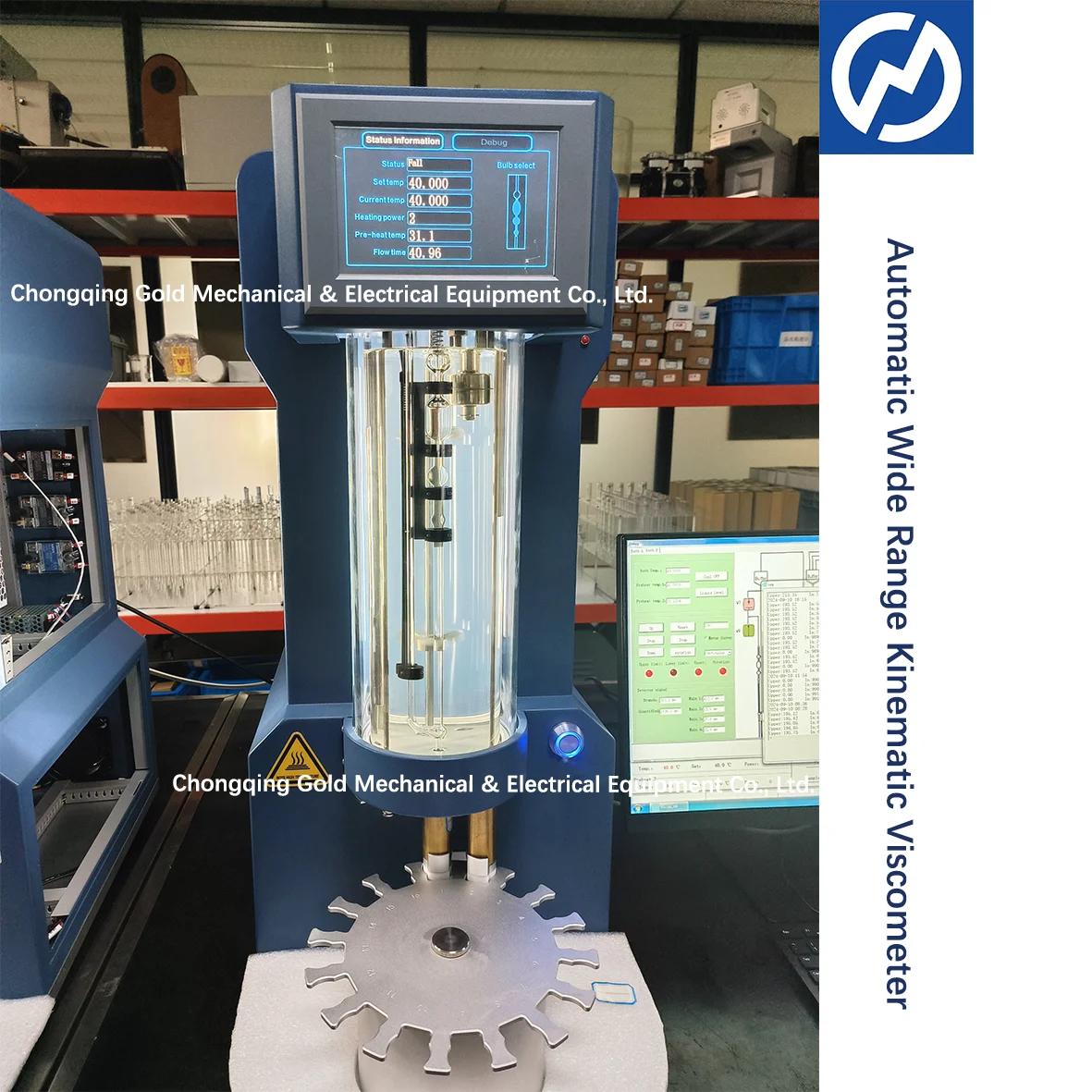

GD-ND21B Fully Automatic Wide Range Kinematic Viscometer

Product Introduction:

Direct tube viscometer testing, compliant with national standards; dual bath dual tube,

Dual 16-bit intelligent sample loading plates,

fully automatic sample loading, fully automatic testing,

Fully automatic cleaning and drying of viscosity tubes;

intelligent sample preheating, automatic cleaning with dual solvents;

Dual baths can be controlled separately to test kinematic viscosities at different temperature points and automatically calculate viscosity indices;

Automatic calibration of viscometer constants;

bath liquid level self-adaptive balance technology, automatic adjustment of thermostatic medium during heating and cooling processes.

Product Features:

1. Equipped with dual 16-bit sample loading plates, capable of 24-hour continuous operation, with automatic completion of sample preheating, loading, measurement, cleaning, drying, result calculation, and repeatability calculation.

2. Dual baths with independent temperature control, allowing for simultaneous dual-channel testing, cleaning, and drying.

3. Utilizing photoelectric or thermistor detection, capable of measuring both transparent and opaque samples, including gasoline, diesel, kerosene, cutting fluids, heat transfer oils, additives, and new and used lubricating oils for Newtonian fluids.

4. Features PTC intelligent sample preheating function, which can automatically control the preheating temperature based on the preset test target temperature of the sample to be measured, with a preheating temperature range from room temperature to 120°C; the preheating rate is 15°C per minute, significantly reducing the time required for sample temperature stabilization during testing.

5. Built-in Peltier cooling system, using the temperature-controlled bath liquid directly as the refrigerant for rapid cooling.

6. Applies bath liquid level self-adaptive balance technology (Patent No.: ZL 2020 2 1531117.X), adapting to large-span adjustments in test temperature, automatically increasing or decreasing the temperature control medium during heating and cooling processes, maintaining the immersion depth of the viscosity tube unchanged.

7. Operated on a Windows system with a fully Chinese interface, simple to operate, user-friendly, capable of connecting to LIMS systems, and can connect to a barcode scanner for automatic sample information entry.

8. The system includes automatic calibration of viscometer constants, as well as auxiliary functions such as temperature calibration, internal clock timing calibration, automatic conversion between kinematic viscosity and Saybolt viscosity, and automatic calculation of viscosity index.

9. Equipped with dual hardware and software overheating protection, overheating alarms, anti-dry burn protection,Prompt when cleaning fluid low, and waste liquid cleanup reminders to ensure safe instrument operation.

10. Features a double-layer glass bath design, PT1000 high-precision temperature sensors, and dual-blade stirring to maintain stable and precise temperature control in the bath, with a temperature control accuracy of 0.005°C.

11. Utilizes an accurate algorithm for sampling conditions to automatically and intelligently select the test ball bubble for unknown samples, with options for intelligent or follow-up selection.

12. Has an automatic intelligent dual-solvent cleaning function, with customizable cleaning modes, cleaning the viscometer while also cleaning the sample cup, eliminating the need for separate sample cup cleaning.

13. Features a timing calibration port, allowing for precise time calibration of the instrument using a standard time calibration instrument.

Performance Indicators:

| Item | Content |

|---|---|

| Performance Indicators | |

| Standard Compliance | ASTM D445, D446, ISO 3104, GB/T 265, GB/T 30515 |

| Temperature Control Accuracy | ±0.005℃ |

| Measurement Range | 0.3~10000 mm²/s<br>Measurement span of two viscometers: 10000 times |

| Timing Resolution | 0.01 seconds |

| Sample Capacity | 16 positions × 2 (32 samples) |

| Repeatability | ≤0.4% |

| Bath Volume | 3 L × 2 (6 liters) |

| Power Consumption | ≤1600W |

| Temperature Range | 20~100℃<br>(with built-in Peltier cooling) |

| Dimensions | Unit A: 400×700×800 mm<br>Unit B: 400×700×800 mm |

| Operating Environment | |

| Power Supply | AC 220V±10%, 50Hz±10% |

| Relative Humidity | <80% RH |

| Ambient Temperature | 10~28℃ |

| Other Requirements | No strong vibrations, airflow, electromagnetic interference, or corrosive gases around the laboratory |

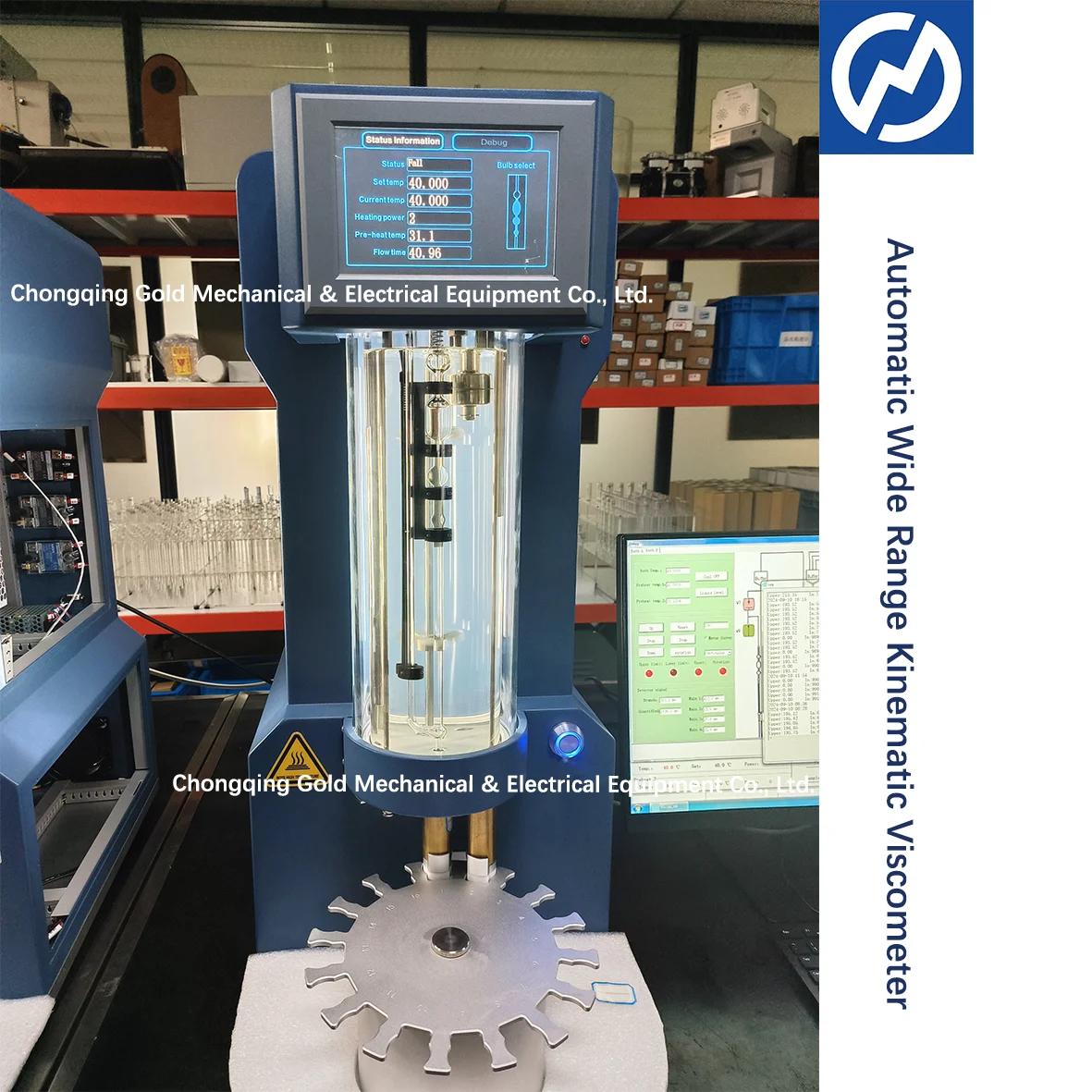

GD-ND21B Fully Automatic Wide Range Kinematic Viscometer

Product Introduction:

Direct tube viscometer testing, compliant with national standards; dual bath dual tube,

Dual 16-bit intelligent sample loading plates,

fully automatic sample loading, fully automatic testing,

Fully automatic cleaning and drying of viscosity tubes;

intelligent sample preheating, automatic cleaning with dual solvents;

Dual baths can be controlled separately to test kinematic viscosities at different temperature points and automatically calculate viscosity indices;

Automatic calibration of viscometer constants;

bath liquid level self-adaptive balance technology, automatic adjustment of thermostatic medium during heating and cooling processes.

Product Features:

1. Equipped with dual 16-bit sample loading plates, capable of 24-hour continuous operation, with automatic completion of sample preheating, loading, measurement, cleaning, drying, result calculation, and repeatability calculation.

2. Dual baths with independent temperature control, allowing for simultaneous dual-channel testing, cleaning, and drying.

3. Utilizing photoelectric or thermistor detection, capable of measuring both transparent and opaque samples, including gasoline, diesel, kerosene, cutting fluids, heat transfer oils, additives, and new and used lubricating oils for Newtonian fluids.

4. Features PTC intelligent sample preheating function, which can automatically control the preheating temperature based on the preset test target temperature of the sample to be measured, with a preheating temperature range from room temperature to 120°C; the preheating rate is 15°C per minute, significantly reducing the time required for sample temperature stabilization during testing.

5. Built-in Peltier cooling system, using the temperature-controlled bath liquid directly as the refrigerant for rapid cooling.

6. Applies bath liquid level self-adaptive balance technology (Patent No.: ZL 2020 2 1531117.X), adapting to large-span adjustments in test temperature, automatically increasing or decreasing the temperature control medium during heating and cooling processes, maintaining the immersion depth of the viscosity tube unchanged.

7. Operated on a Windows system with a fully Chinese interface, simple to operate, user-friendly, capable of connecting to LIMS systems, and can connect to a barcode scanner for automatic sample information entry.

8. The system includes automatic calibration of viscometer constants, as well as auxiliary functions such as temperature calibration, internal clock timing calibration, automatic conversion between kinematic viscosity and Saybolt viscosity, and automatic calculation of viscosity index.

9. Equipped with dual hardware and software overheating protection, overheating alarms, anti-dry burn protection,Prompt when cleaning fluid low, and waste liquid cleanup reminders to ensure safe instrument operation.

10. Features a double-layer glass bath design, PT1000 high-precision temperature sensors, and dual-blade stirring to maintain stable and precise temperature control in the bath, with a temperature control accuracy of 0.005°C.

11. Utilizes an accurate algorithm for sampling conditions to automatically and intelligently select the test ball bubble for unknown samples, with options for intelligent or follow-up selection.

12. Has an automatic intelligent dual-solvent cleaning function, with customizable cleaning modes, cleaning the viscometer while also cleaning the sample cup, eliminating the need for separate sample cup cleaning.

13. Features a timing calibration port, allowing for precise time calibration of the instrument using a standard time calibration instrument.

Performance Indicators:

| Item | Content |

|---|---|

| Performance Indicators | |

| Standard Compliance | ASTM D445, D446, ISO 3104, GB/T 265, GB/T 30515 |

| Temperature Control Accuracy | ±0.005℃ |

| Measurement Range | 0.3~10000 mm²/s<br>Measurement span of two viscometers: 10000 times |

| Timing Resolution | 0.01 seconds |

| Sample Capacity | 16 positions × 2 (32 samples) |

| Repeatability | ≤0.4% |

| Bath Volume | 3 L × 2 (6 liters) |

| Power Consumption | ≤1600W |

| Temperature Range | 20~100℃<br>(with built-in Peltier cooling) |

| Dimensions | Unit A: 400×700×800 mm<br>Unit B: 400×700×800 mm |

| Operating Environment | |

| Power Supply | AC 220V±10%, 50Hz±10% |

| Relative Humidity | <80% RH |

| Ambient Temperature | 10~28℃ |

| Other Requirements | No strong vibrations, airflow, electromagnetic interference, or corrosive gases around the laboratory |